Cross Docking

BeOne transit warehouse management system

For complete management of logistics activities, Nova Systems has developed in BeOne "Cross Docking", the integrated functionality that allows the management and control of all types of activities within the transit warehouse, starting with the marking of goods arriving from several destinations and which can be either unloaded and reloaded directly onto other vehicles without stopping on the ground, or stored in transit areas when handling is not immediate.

How Cross Docking warehouse management system works:

The main functions of the additional service developed by the Nova Systems Development Centre are "Arrival of goods for collection", "Positioning of goods in the warehouse", "Exit of goods from the warehouse", creation of a Loading Unit (UDC) and "Transfer of packages between warehouse areas". Cross Docking" allows you to manage both goods originally marked by the sender and goods without a label. It is also possible to label on the pick-up vehicle, at unloading at the flap, with pre-printed labels or labels generated by the Beone software solution on arrival.

The Radio frequency terminals allow goods to be routed directly to the neck marker reading, either at unloading or loading of the vehicle, thus increasing business performance. Radio frequency management of loading and unloading bays, as well as temporary storage areas, allows you to keep the flow of goods under control at all times. With radio frequency terminals you also have the possibility of detecting the dimensions of the goods as soon as they arrive in the warehouse, thus giving the operators in the office the possibility of having immediate information on any discrepancies between what is declared by the customer and what is actually unloaded from the vehicle.

This is what BeOne Cross Docking warehouse allows you to do:

- Radio frequency reading

- List and individual shipment verification

- Static and Dynamic Assignment of Reading Missions

- Creation and management of UDCs (Unit Load Units) for faster reading

- Use of pre-printed labels or printing of labels on arrival for greater flexibility of use

- Reporting of anomalies at Goods and List level

- Positioning of goods in the warehouse according to zone and time criteria

- Reporting of bulky goods

- Availability of reading data for analysis and statistics

Discover all the advantagesTHE ADVANTAGES

Arrival verification

Arrival verification

- Timely and punctual control of incoming goods

- Immediate updating of shipment data: eliminates the time needed to transfer information from the warehouse to the operations department

Positioning

Positioning

- Faster retrieval of goods

- Improved utilisation of warehouse space

Departure verification

Departure verification

- Increased efficiency and safety during loading

- Automatic updating of progress reports

Inventory control

Inventory control

- Control of goods in a given warehouse area

Cross Docking - WMS

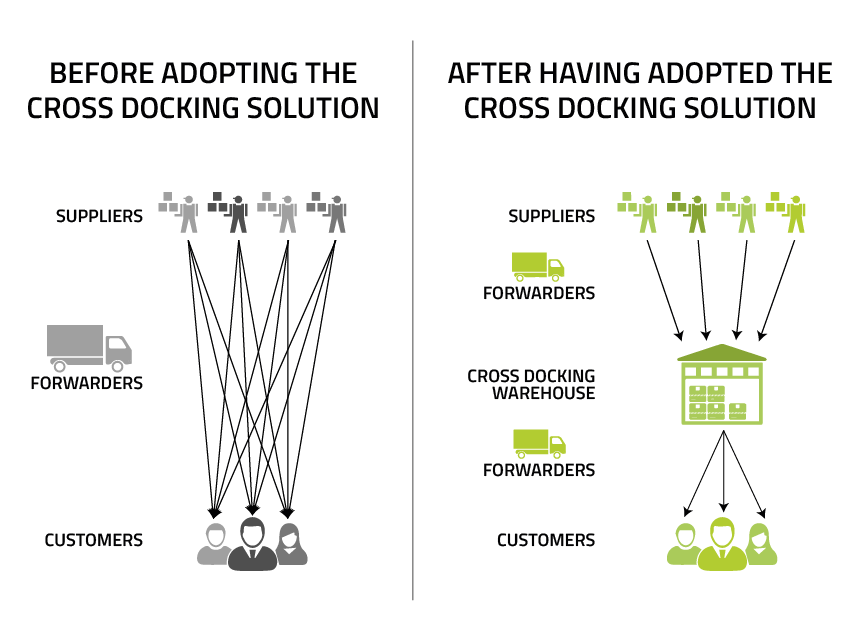

Cross Docking is a function that enables merchandise arriving in the warehouse to be traced. The new function of Cross Docking has been implemented in BeOne, which enables the controlled management of the handling of warehouse merchandise, incoming and outgoing, be it merchandise left briefly on the ground or, alternatively, passing from one vehicle to another.

Thanks to Cross Docking, the logistics flows can be improved, increasing the efficiency and precision of the handling operations and contributing, at the same time, to the reduction of the costs.